Vibro System - Double disc fertilizer spreaders

During their function, these metal agitators collide against the fertilizer and cause friction or abrasion among granules, with subsequent breaks of the product and alteration of its nutritional characteristics; as a matter of fact, a broken or pulverized fertilizer immediately releases its properties to the ground instead of diluting them in a longer length of time, with the risk of instant over-fertilization and possible pollution of water strata.

Another inconvenience caused by agitators is the production of heat during use. This heat is transmitted to the fertilizer and, together with the grinding and pulverizing phenomena, it causes the formation of lumps that can partly or totally obstruct the orifices of the spreading system.

Furthermore should a spreader be used to distribute seeds, the agitator rotation can damage the seeds. The damaged seeds will obviously never sprout.

Years of research and development in lab and in field, led our company to the creation of the “VIBRO SYSTEM”, an innovative stainless steel system made of a vibrant disc mounted at the hopper bottom and above the feed system. When engaging the PTO shaft, the hopper bottom starts to vibrate, and keep on doing so for the entire distribution lapse of time.

A stainless steel sieving grid is solidly applied above the vibrating bottom. It has three main functions:

– retaining the fertilizer lumps that if were reaching the orifices of the quantity calibration system could block the constant and regular functioning of the feed and distribution system;

– guaranteeing the fertilizer flow towards the vibrating bottom also in presence of consistent quantities of lumpy product (thanks to the vibration);

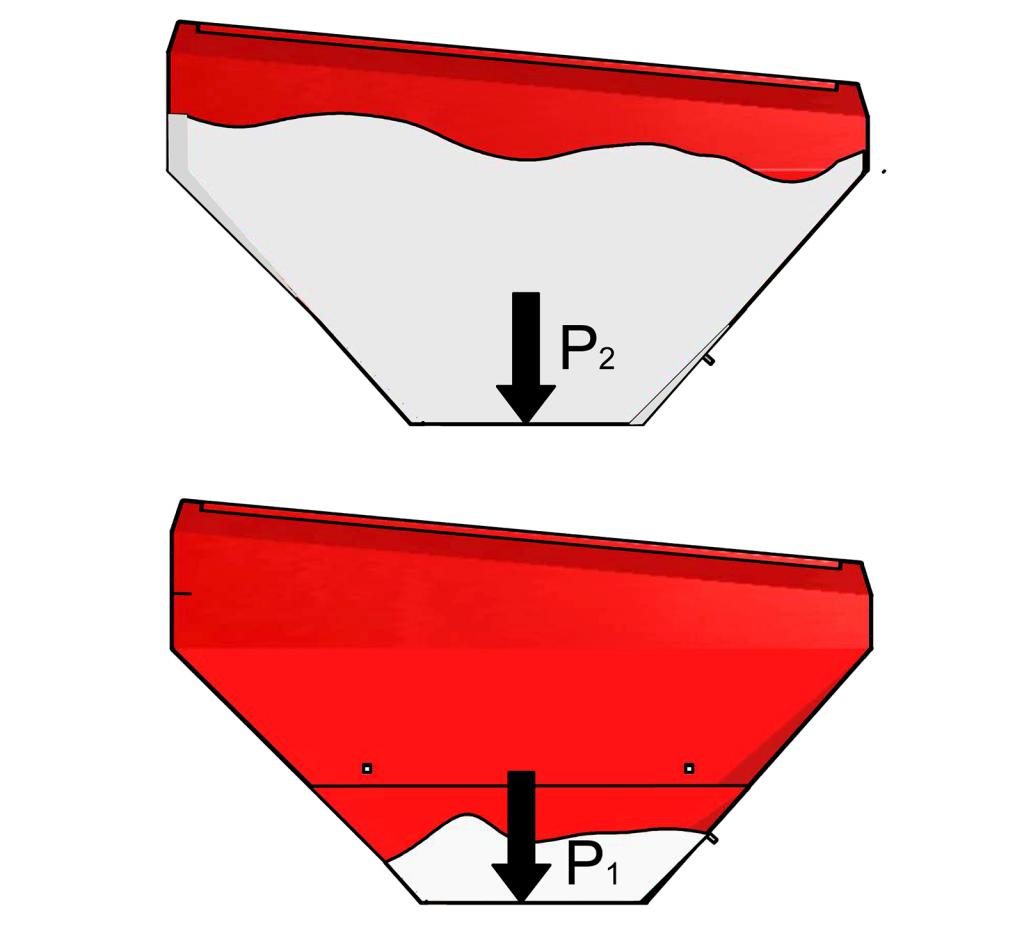

– decreasing and maintaining constant the fertilizer pressure on the feed system in order to distribute a constant and continuous dose of fertilizer with any volume of product inside the hopper.

With the “VIBRO SYSTEM”, it is now possible to distribute products like powdered lime, sulphates, pellets or organic amenders that cannot normally be spread with traditional systems; it is furthermore advisable to use the VIBRO SYSTEM for the broadcast sowing of various seeds and wet rice; granules reach the distribution system without losing their potentiality to sprout, which can be compromised by frictions due to scrubbing or incisions normally caused by the rotation of agitators inside the product.